QRR Chemical Engineering Optimization

Acetone/Water Distillation Column Case Study

Software-only solution

No hardware upgrades • Compatible with all DCS/PLC systems

Process & Problem

System Specifications

- Binary distillation: Acetone/Water separation

- Feed rate: 100 kmol/hr

- Column: 15 trays, atmospheric pressure

- Target: >99.5% acetone purity

Critical Challenges

- Fouling and energy losses - Progressive efficiency degradation

- Off-spec production - Quality inconsistencies

- Rising maintenance costs - Reactive approach

- High operating costs - Baseline: ~$1.2M per year

Traditional fixed-parameter control cannot adapt to changing conditions

QRR Modeling Approach

Comprehensive simulation tracking all critical parameters

Simulation Parameters

Tracks tray efficiency, flooding risk, energy use, fouling progression, and maintenance cycles in real-time

Conventional Control

- Fixed energy input parameters

- Reactive maintenance scheduling

- No predictive management

- Manual operator adjustments

QRR-Optimized

- Adaptive control systems

- Predictive fouling management

- Real-time optimization

- Automated performance tuning

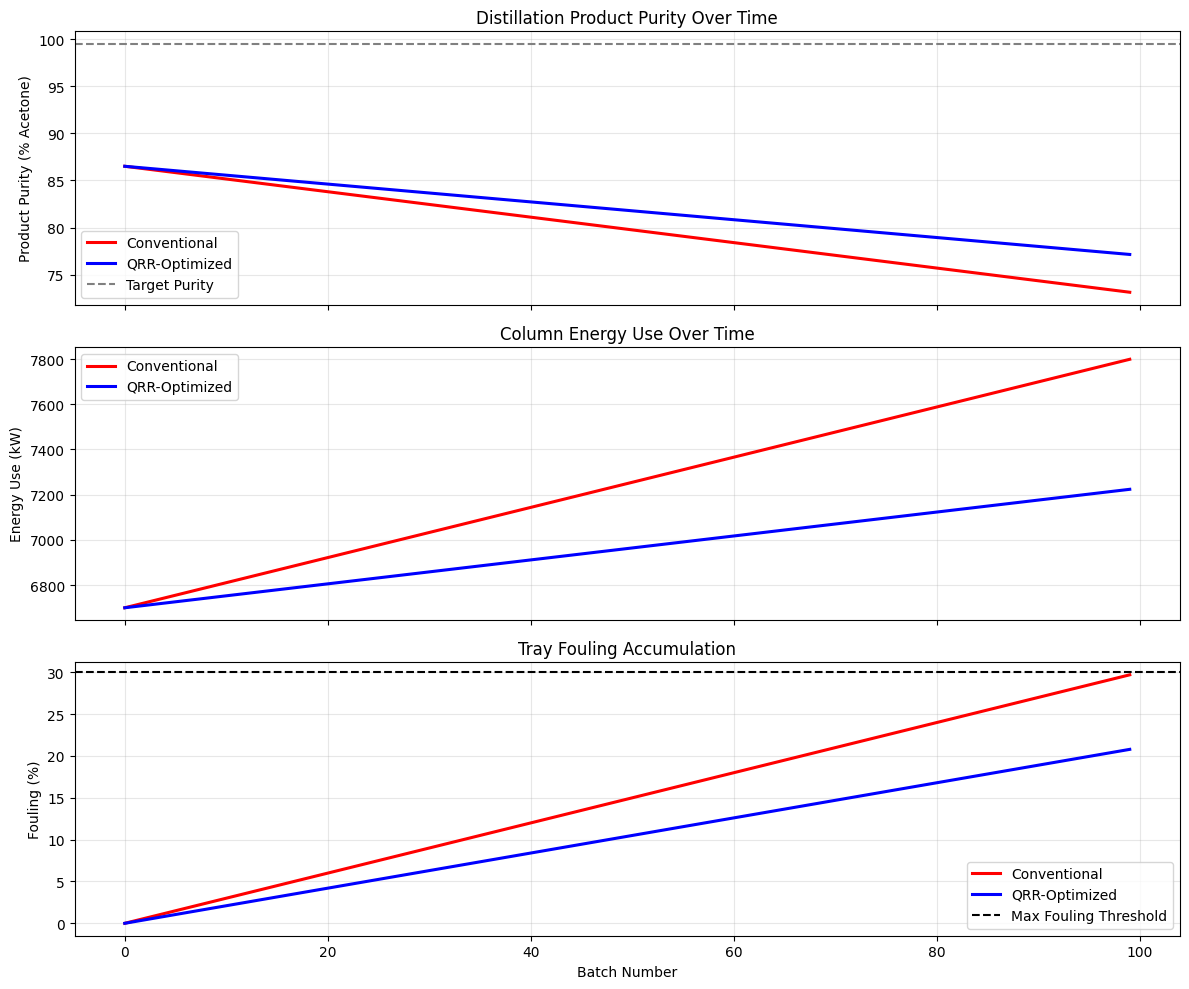

Validated Performance Results

Comprehensive analysis across all key performance indicators

QRR optimization delivers measurable improvements across all metrics

Business Impact

Zero-Risk Value Proposition:

- No upfront investment - You don't pay until you see results

- Compatible with existing systems - All DCS/PLC platforms

- Rapid deployment - Weeks, not months

- Scalable across facilities - Replicate success plant-wide

Beyond Distillation

QRR optimization applies across your entire chemical engineering workflow

🔥 Reaction Vessels

- Temperature optimization

- Conversion efficiency improvement

- Catalyst life extension

♨️ Heat Exchangers

- Fouling prediction & prevention

- Energy efficiency gains

- Predictive maintenance scheduling

🌀 Separators

- Product purity control

- Throughput optimization

- Pressure management

⚗️ Crystallizers

- Crystal size distribution control

- Yield maximization

- Quality consistency

Transform Your Process Efficiency

Ready to optimize your chemical processes?

Potential Plant-Wide Impact

Typical Chemical Plant: 10-20 major process units

Average Savings per Unit: $50-200K annually

Plant-Wide Potential: $500K - $4M Annual Savings

Schedule a Process Assessment

Robin Macomber

relationalrelativity@gmail.com

805-621-0987

Relational Relativity LLC — Optimizing Chemical Processes Through Mathematics